News

See below for our latest GeMech news

Home » GeMech News

See below for our latest GeMech news

The start of the new year has been frantic at GeMech, with new projects started and large projects continued through January and February, with March looking equally busy and a catalogue of work for April.

January and February has seen us continue CFA piling works for ISG at their prestigious Fairwater Campus development in Cardiff, with load testing completed in January, works are aiming to finish mid-March.

Our largest rig in the fleet, the Comacchio CH450 moved from Cardiff to Stratford to complete CFA piling work for repeat client Watkin Jones on a new student accommodation development.

Our driven pile crews have also been busy, utilising our newly adapted precast driven piling rig. GeMech installed 250mm square precast concrete piles to varying depths in Weston-Super-Mare, with further precast driven pile projects on the horizon. Thanks to the versatility of the Vermeer HL2500, the crews have also been busy installing steel cased bottom driven piles for clients LCB Group, ADRA Homes.

And finally our ground improvement projects have taken off, with our CAT 330 and ABI TM11 being put through their paces installing stone columns in Slough for Francis Construction and Stafford for Spellar Metcalfe. The CAT 330 installing 1,300 stone columns to provide improved ground bearing capacity for two new warehouse units, and the ABI TM11 installing 600 columns. Once completed, these rigs will be moving on to sites in Basingstoke and Bristol, keeping them busy until mid-April.

GeMech specialists and our fleet were down on site in Weston-Super-Mare for repeat client Curo Group, installing over 400nr. 300mm diameter CFA augured piles for housing plots on the former RAF Locking site. Using the versatile GEAX EK110, we are installing piles in to Mercia Mudstone from 4.5m depth and terminating at a maximum depth of 6.0m. Whilst the geology around Weston-Super-Mare generally is suited for a driven piled solution to be used, the ground conditions on this site called for an augured piling method.

We are pleased to be working again with Curo Group, providing a robust and cost effective solution.

Driven precast concrete piling is being added to the GeMech repertoire. We have an exciting update on our “drive” to offer more engineering solutions for our valued clients. Our colleagues at AGD Equipment LTD have been busy this last week transforming one of our steel cased bottom driven piling rigs in to a restricted access precast concrete piling rig. As well as being able to offer a solution, where vibration and noise restrictions may apply, we are still able to provide an efficient alternative in steel casings. Once the rig is adapted, we will be able to offer up to 250mm square precast concrete piles in as little as 7.0m headroom up to any length depending on ground conditions.

GeMech are looking forward to adding the adapted machine to our fleet, and will be putting it to work in Haywards Heath in two weeks time.

A great image from our foreman Rob Wright on site in Wolverhampton, where we’re installing 15.0m deep 350mm diameter contiguous pile walls in to Mudstone for repeat client Speller Metcalfe, to form a perimeter wall around a pre-existing mine shaft which has been grouted prior to commencement. Once these operations have been completed, we will be returning to site at a later date to provide a ground improvement solution using vibro-stone columns.

We’re installing steel cased bottom driven piles inside an existing warehouse in Avonmouth. With restricted headroom of between 6.0m – 5.5m, the mast on our Vermeer HL-2500 is able to reduce down to allow it to work in tight access sites without compromise on performance. A total of 107nr. 220mm steel casings driven to 12.0m with refusal on the Mercia Mudstone.

We’re finishing off the week in style piling down on Lower Bristol Road for Watkin Jones Group with our Comacchio SpA CH450, installing 350mm, 450mm and 600mm diameter CFA piles through alluvial soils and socketing in to bedrock below. 🏗️👷♂️

We’ve been busy behind the scenes here at GeMech, with numerous contract awards and our website update.

As the sun begins to shine again, we will be getting plenty of exciting images of this CFA piling project!

The first in a while, showcasing the ABI EQUIPMENT LIMITED TM14 installing stone columns alongside our GEAX srl EK75 on site in Southampton 🏗️👷♂️

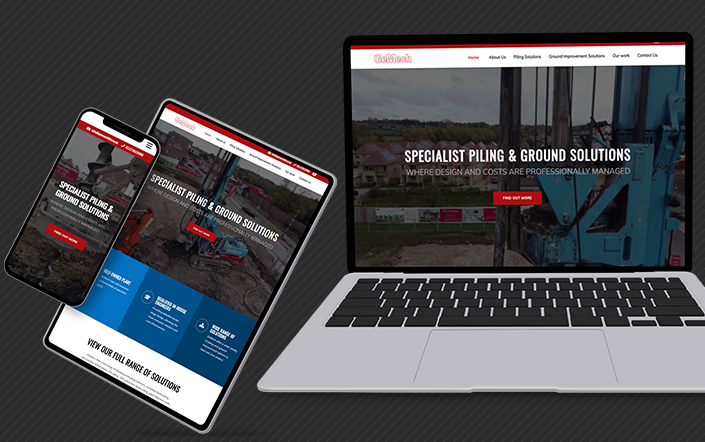

GeMech are very excited to have finally launched a new website – after a fair few months of hard work!

As GeMech has grown as a business, we wanted to be able to showcase our wide range of solutions and services to our customers (old and new), in the simplest way possible. Our aim was to create a modern-looking website that enabled everyone to access the information they needed, quickly and easily.

Understanding exactly how our process works when proposing and implementing a solution from start to finish can be a bit confusing – so we took out the confusion and simplified it into three simple steps.

When looking for the right piling or ground improvement solution, there may be specific capabilities that are required, or advantages that would be a benefit to know about. To help with this, we provided simplistic explanations of each of our solutions that include their main capabilities and benefits, along with information on what they are and how they work.

Our aim is to deliver excellent service and value and we are committed to delivering measurable results and currently serve over 250 customers annually. To illustrate in real-life how our solutions have made tangible differences for our customers, we decided to provide a number of informative case studies that showcase different techniques used within projects that we have successfully completed for them.

Unit 12 Kenn Court,

South Bristol Business Park,

Roman Farm Rd,

Bristol BS4 1UL,

United Kingdom

Tel: 01173015480

E-mail: info@gemechltd.co.uk

Metro Centre,

28 Dwight Rd, Northwood,

Watford WD18 9SB,

United Kingdom

E-mail: info@gemechltd.co.uk